Environmentally Aware Products and Services

Relevant SDGs

As a manufacturer, we are expected to contribute to resolving social issues, such as environmental concerns, through our core business. Our Group, focuses on creating products and services that enhance environmental performance, always leveraging the principles of “craftsmanship, compactness, and frugality.” We do this by thinking critically about product lifecycles, reducing the use of chemicals, and by emphasizing energy efficiency, resource conservation, and biodiversity conservation. We are dedicated to the creation of products and services that contribute to improving or conserving the environment.

Green Product Labeling System

Environmentally Considerate and Contributing Products

Our Group has introduced its own “Green Product Labeling System”※. Departments other than those applying for Green Product certification are welcome to participate in the certification review. The involvement of other departments not only ensures a more objective and comprehensive assessment, but also facilitates the exchange of information related to environmentally conscious design among different departments.

※ This system is based on one that Seiko Instruments first introduced in 2001. From 2020, it became the Group’s official Green Product Labeling System. By 2023 it was being implemented throughout Seiko Instruments and Seiko Watch Corporation, and we are now looking at expanding it to the entire Group.

Green Product Certification Criteria

- We established our own product-specific 5-level evaluation criteria based on the Environmental Label Type Ⅱ (ISO 14021). This evaluation takes into account various environmental factors. Products that score an average of at least 3.5 points out of 5 are certified as “Green Products.”

- Starting from fiscal year 2022, we made significant revisions to these criteria to address issues related to decarbonization and ocean plastics.

- We have expanded our Green Product criteria by adding environmental considerations such as “Scope 3 Calculation,” “Collaborative Requests to Suppliers for Decarbonization,” and “Reduction of Scope 1 and 2.” This modification aims to create a system that addresses greenhouse gas reduction from a broader perspective.

- We have made traditional environmental considerations such as, “using reusable parts” or “using parts made from recycled materials” and “making packaging smaller or lighter” into standards that include the management of plastic materials. This helps to raise awareness of reducing the use of plastics while also aligning with the Law for the Promotion of Recycling Plastic Resources.

| Score | The concept of absolute evaluation criteria | The concept of relative evaluation criteria |

|---|---|---|

| 5 points | Top class | Outstanding improvement over prior products |

| 4 points | First group | Substantial improvement over prior products |

| 3 points | Second group | Some Improvement over prior products |

| 2 points | Average level | Same level as prior products |

| 1 point | Low level | Lower level than prior products |

25 Key Items Relating to Environmental Friendliness Used in Green Products Certification Criteria*

- Power consumption in use

- Power consumption in standby

- Product weight

- Use of reusable parts and parts made of recycled materials (including plastic materials)

- Recyclability of used products

- Longer product life

- Reduction of substances to be avoided*1 contained in goods

- Prohibition of the use of conditionally banned substances*1 in goods

- Prohibition of the use of banned substances*1 in goods

- Smaller or lighter packaging (including plastic materials)

- Reduced use of foam in packaging

- Avoidance of the use of polyvinyl chloride and heavy metals in packaging

- Energy conservation in the manufacturing process

- Scope 3 Calculation

- Resource conservation in the manufacturing process

- Reduced use of substances to be avoided*1 in manufacturing processes

- Prohibition of the use of banned substances*1 in the manufacturing process

- Implementation of Green Purchasing

- Requesting cooperation from suppliers to decarbonize

- Ease of disintegration operations

- Ease of sorting

- Information disclosure in instruction manuals, etc.

- Contribution to improving the environmental performance of our customers' products and preserving the environment we all share

- Consideration for biodiversity

- Reduction of Scope 1 and 2*2

*1 According to the standards set by the Seiko Group

*2 Evaluation of the introduction of renewable energy in the production process

High Grade Green Products Certification System

High Grade Green Products Certification Criteria

Products that not only meet the Green Products Certification Criteria, but also meet the following two conditions will be certified as High Grade Green Products.

| Basic condition | Must satisfy the Green Products Certification Criteria, with an average score of 3.5 or more. |

|---|---|

| Additional conditions |

|

Management of Chemical Substances in Products

The strengthening of product-related chemical regulations stemming from the EU's RoHS directive is expanding globally. Within our Group, we are not only committed to eliminating substances that are prohibited by regulations, but also eliminating or severely reducing those that pose concerns about harming human health and the environment.

Business units involved in product manufacturing have all established management systems, working towards the elimination of such substances through aggressive initiatives and regular confirmation analyses. Additionally, different environmental regulations may require different types of labels. Depending on the country or region, labeling requirements for substances, means of disposal, and other information may vary. Business units handling relevant products ensure that labeling is done in accordance with the relevant requirements.

Examples of Environmentally Conscious Products and Services

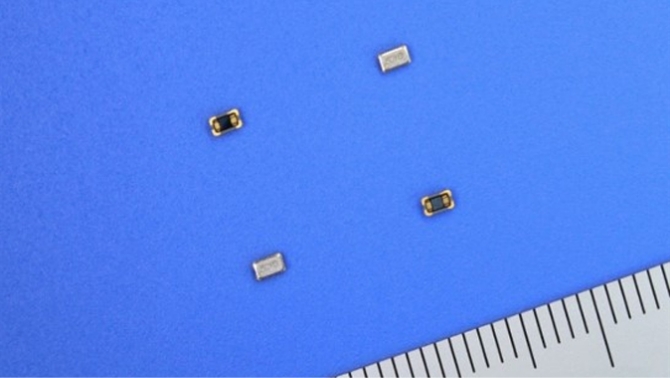

Industry-Leading Low Power Consumption of 0.8μA

3.3V resistant, high capacity, and excellent charge-discharge cycle characteristics

A label mobile printer that meets all expectations in a small body

A simple, compact, easy-to-use metronome with a lightweight design, featuring only the most frequently used functions and settings.