Climate Change

Relevant SDGs

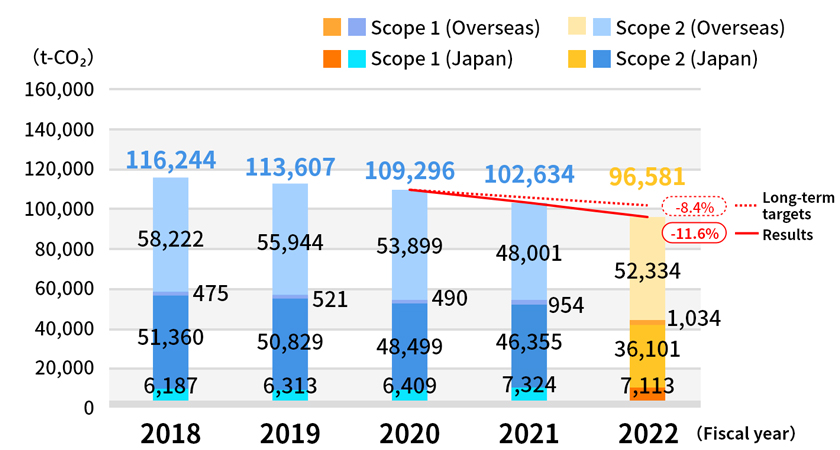

To help achieve a decarbonized society, we have set long-term environmental targets, and are working to reduce greenhouse gas (GHG) emissions across all business activities at all our worldwide operations.

Basic Approach

As the business risks associated with climate change, such as the increasing frequency of natural disasters, continue to rise, the role and responsibility of companies in achieving a "decarbonized society" are becoming increasingly significant.

Our Group’s policies are based on several climate change agreements, including the Paris Agreement, and Japan's net-zero policy. We report to the Government on energy usage, progress towards energy-reduction goals, and greenhouse gas emissions, in accordance with national climate change regulations such as the Energy Efficiency Act (Act on Rationalizing Energy use and Shifting to Non-fossil Energy), and the Act on Promotion of Global Warming Countermeasures.

Our Group is committed to reducing greenhouse gas emissions as part of the SDGs strategy outlined in our 8th Medium-Term Management Plan, called "SMILE145," which includes initiatives for climate change and decarbonization.

Our efforts to reduce GHG emissions focus on energy-saving activities that target both CO₂ and other greenhouse gases, the introduction of renewable energy, and emissions reductions across the value chain. Additionally, we emphasize creating energy-efficient products and services by including power consumption as one of our environmental considerations.

In terms of energy-saving activities, we promote efficient operation and management of all equipment, and we are updating many units to high-efficiency models. We are also continuing to pursue everyday energy-saving activities, believing that these efforts need to be continuous in order to be truly effective. There are various types of renewable energy, and we believe it is essential to adopt the optimal method according to the location and characteristics of each business site. We intend to promote reductions across the value chain together with our suppliers and other stakeholders.

Long-term target

In November 2023, the Group revised its long-term target to reduce greenhouse gas emissions ahead of schedule. In terms of electricity supply, we aim to achieve 100% renewable energy at all our sites, both domestic and overseas, by the end of fiscal 2040. We plan to offset residual emissions from energy conservation, fuel conversion, and Scope 3 reductions by introducing elimination credits.

In line with this long-term goal, we will continue to accelerate our adoption of renewable energy and make efforts to further reduce greenhouse gas emissions. Regarding our targets for fiscal year 2030, we have obtained certification from the Science Based Targets initiative (SBTi), confirming that our targets align with the 1.5°C target set out in the Paris Agreement.

Our long-term targets for reducing greenhouse gas emissions

Greenhouse gas emissions reduction target

Fiscal year 2030

Scope1、242% reduction compared to the FY2022 level.

Scope325% reduction compared to the FY2022 level, targeting categories 1 and 11.

Fiscal year 2050

Aiming for net zero.

Summary of Fiscal Year 2023

In 2023, we continued to focus on converting air conditioning equipment to high-efficiency models and converting all lighting fixtures to LEDs as part of our energy-saving activities. Looking at renewable energy, we continued switching to electricity derived from renewable sources, and increased our ratio of renewable energy to 18.9%. As a result of these efforts, GHG emissions in Scope 1 and 2 amounted to 79,965 tons of CO₂, a reduction of approximately 17% compared to the previous year.

To help reduce GHG emissions across the value chain, we focused on emissions during product transportation, and promoted modal shifts, such as changing the transportation of some products from air to sea. Our total Scope 3 emissions in 2023 were 568,674 tons of CO₂, a reduction of approximately 0.7% compared to the previous year.

Scope1, 2 Greenhouse Gas (GHG) Emissions

79,965t-CO₂

- Scope 1: Direct emissions by the business operator (e.g., fuel combustion)

- Scope 2: Indirect emissions from the use of electricity supplied by other companies (market-based)

- ■Scope of Data Aggregation:

- ・Seiko Group Corporation and all its Group companies

・Includes greenhouse gases other than CO₂

・Excludes biogenic GHG emissions - ■Emission Factors:

-

- ・Electricity:

- Japan sites: Use "Emission Factors by Electric Power Company" from the government’s Act on Promoting Global Warming Countermeasures

Overseas sites: Use the emission factors of each country based on data from the International Energy Agency (IEA)

- ・Fuel: Uses the "Calculation Methods and Emission Factors List" from the Act on Promoting Global Warming Countermeasures

- ・Greenhouse gases other than CO₂: ・Uses the "Calculation Methods and Emission Factors List" from the Act on Promoting Global Warming Countermeasures

Note: Due to rounding, the total GHG emissions and the sum of the individual numbers may not match.

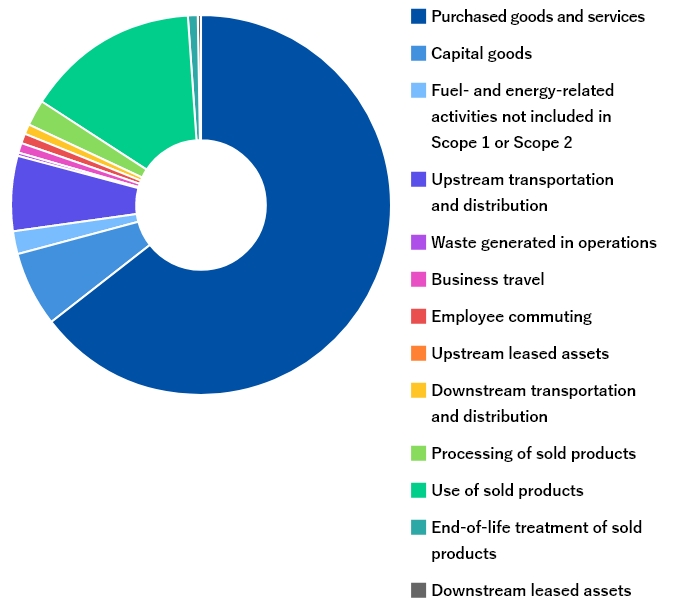

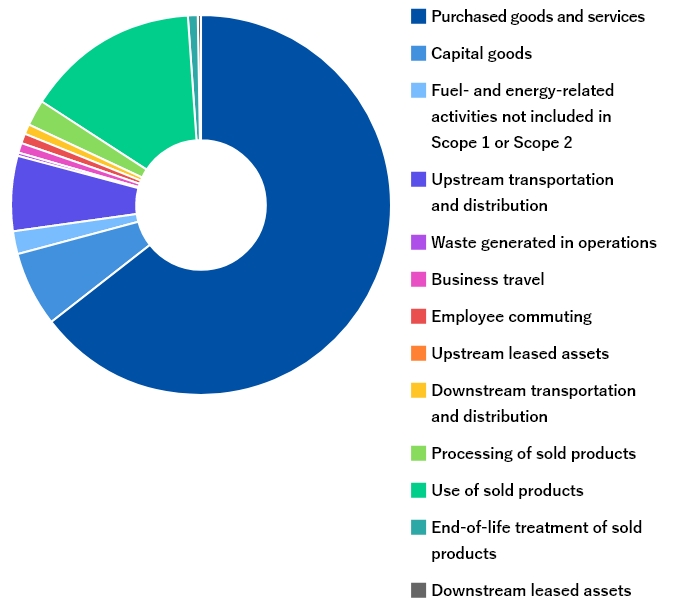

Scope3 Greenhouse Gas Emissions

| Category | Item | CO₂ emissions (t-CO₂) | % |

|---|---|---|---|

| Category 1 | Purchased goods and services | 366,505 | 64.4% |

| Category 2 | Capital goods | 36,082 | 6.3% |

| Category 3 | Fuel- and energy-related activities not included in Scope 1 or Scope 2 | 12,399 | 2.2% |

| Category 4 | Upstream transportation and distribution | 35,093 | 6.2% |

| Category 5 | Waste generated in operations | 2,464 | 0.4% |

| Category 6 | Business travel | 4,506 | 0.8% |

| Category 7 | Employee commuting | 5,380 | 0.9% |

| Category 8 | Upstream leased assets | 122 | 0.0% |

| Category 9 | Downstream transportation and distribution | 3,476 | 0.6% |

| Category 10 | Processing of sold products | 12,469 | 2.2% |

| Category 11 | Use of sold products | 84,896 | 14.9% |

| Category 12 | End-of-life treatment of sold products | 4,573 | 0.8% |

| Category 13 | Downstream leased assets | 708 | 0.1% |

| Category 14 | Franchises | - | - |

| Category 15 | Investments | - | - |

| total | 568,674 | 100.0% |

*The total amount may not match due to the processing of fractions.

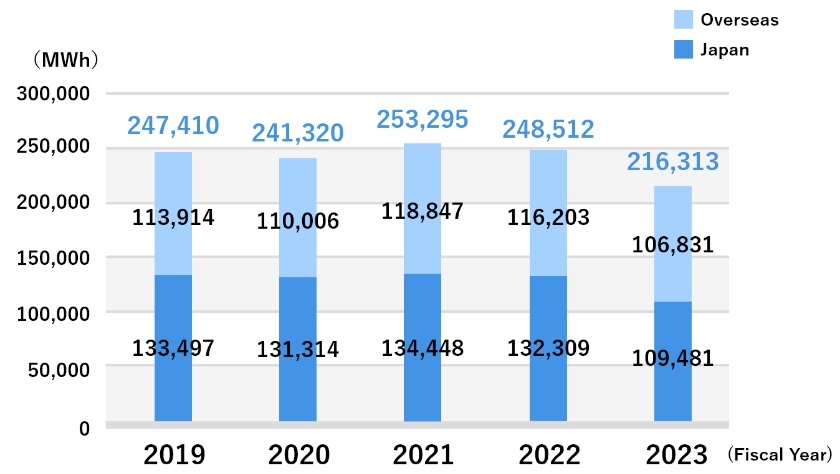

Energy Usage

216,313MWh

Aggregation Scope: Seiko Group Corporation and all its business units

Emissions of Fluorinated Gases

Our Group has completely eliminated the use of ozone-depleting substances in our manufacturing processes. However, we still possess refrigerants used in air conditioning and refrigeration equipment. Each business unit adheres to the Fluorocarbons Emissions Control Act*, conducting inspections and regular check-ups to prevent leaks during usage, as well as specific measures during disposal.

*Japanese Law

Examples of Initiatives

Certified as Green Industry Level 4

In 2023, two factories belonging to Seiko Instruments (Thailand) Ltd. received Level 4 certification in the Green Industry Project organized by Thailand’s Ministry of Industry. The Green Industry Project is a program aimed at raising awareness within industry and promoting sustainable industrial development in response to environmental and social issues. The certification is granted on a scale from Level 1 to Level 5, based on the level of contribution to the environment. In Level 4 (Green Culture), all individuals working in a factory must have a sense of responsibility towards society and the environment.

Even after achieving Level 3, Seiko Instruments (Thailand) Ltd. continued its efforts, with the full cooperation of its employees, and thus attained Level 4 certification. The company engaged in various activities to foster a corporate culture in which everyone in the factory takes responsibility and acts with consideration for the environment and society. These efforts were highly praised by the Thai judges, who noted that each employee demonstrated a high level of awareness and practical application of environmental consciousness.

Audit Scene/Certification Document

Introduction of Renewable Energy

Our Group is accelerating the introduction of renewable energy.

In 2023, we introduced solar power generation at Seiko Manufacturing (Singapore) Pte. Ltd.

The annual power output is approximately 1.55 million kWh, providing about 10% of the site’s total electricity.

Seiko Manufacturing (Singapore) Pte. Ltd.

At Seiko Precision (Thailand) Co., Ltd., solar panels were installed on the roofs of the buildings, and the solar power generation systems started operation in January 2023 for the first factory and in August 2023 for the second factory. The system capacity is 723.2 kW for the first factory and 869.4 kW for the second factory.

Seiko Precision (Thailand) Co.,Ltd

Seiko Instruments (Thailand) Ltd. is the Group company with the highest CO₂ emissions. Solar panels were installed on the roof of its Gateway factory in 2022, and the solar power generation system started operation in February 2023.

Our group will continue to promote the introduction of renewable energy and working to reduce CO₂ emissions.

Seiko Instruments(Thailand)Ltd.