Relevant SDGs

For companies using resources to provide products and services, resource circulation is a critical management issue. The responsibility to contribute to the formation of a “circular society” has become increasingly important.

Within our group, we use various resources, including mineral resources and plastics to manufacture our products, and paper resources in our factories and offices. We adhere to the 3Rs principle (Reduce, Reuse, Recycle) throughout the entire product lifecycle, from raw material extraction to disposal and recycling. Leveraging the traditional “Craftsmanship, Miniaturization, and Efficiency” approach, we strive to use resources efficiently and reduce waste.

We prioritize measures such as designing better products so as to extend usable lifespans, reducing size and weight, and using recycled materials and resource recovery.

Summary of Fiscal Year 2022

In FY2022, we continued our efforts towards resource circulation, including improvements in the yield from materials, downsizing of products, and the reuse of cleaning agents. In office operations, we promoted paperless initiatives by advancing digitization. As a result, we achieved a reduction of 23 tons in waste emissions, accounting for 0.4% of our total emissions.

We will continue these activities in the future, while continuing to strengthen resource circulation efforts in our products, including reducing plastic packaging and digitizing warranty and instruction documents.

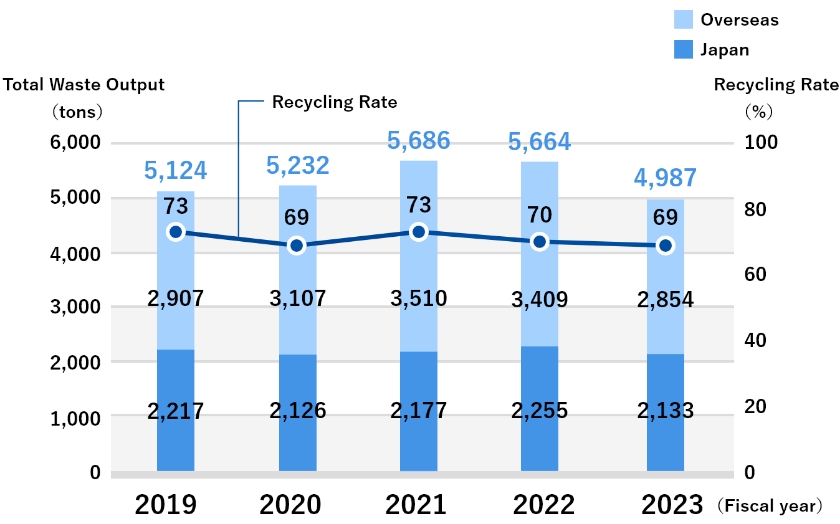

Total Waste Output and Recycling Rate5,664 tons

※The recycling rate includes heat recovery.

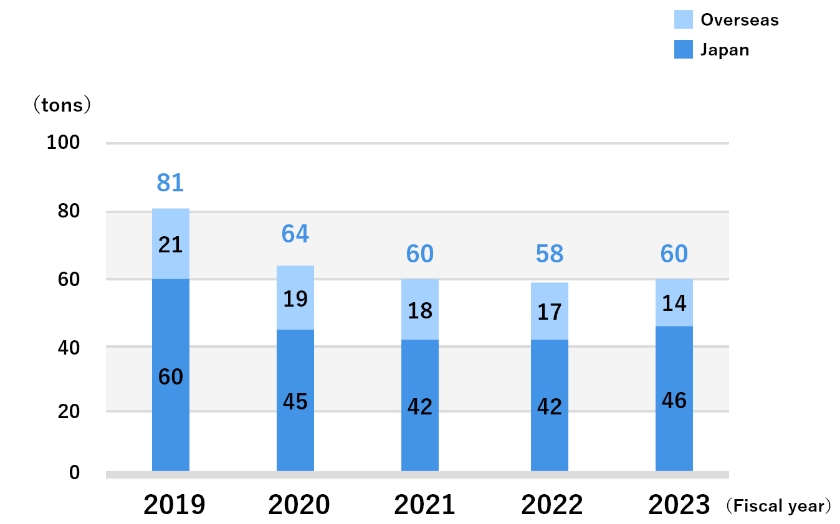

Paper Usage58 tons

Life Cycle Initiatives

Development and Design

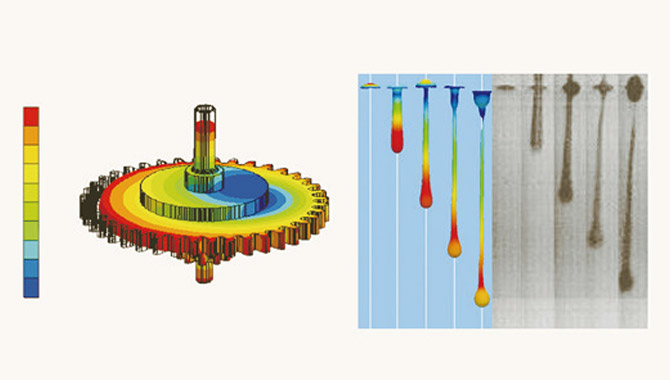

In the product development and design stages, we utilize computer simulations to analyze phenomena that are not visible to the naked eye, such as the stress impacting component materials and the resin flow state of molded parts. These simulations are valuable for confirming design and product performance. We also use supercomputers and parallel computing software for three-dimensional flow analysis of liquid ink ejected from inkjet printer heads. These analyses contribute to improving product performance, shortening the design period, and reducing environmental impact through virtual-trial prototyping, leading to reductions in energy and material use.

Manufacturing

In our manufacturing subsidiaries, we consistently focus on resource circulation based on the fundamental 3Rs principle (Reduce, Reuse, Recycle). Activities such as reducing the use of chemical substances in the manufacturing process and emphasizing reuse and recycling practices are integral to our daily operations. We also recycle water resources, recognizing that water is a valuable natural capital.

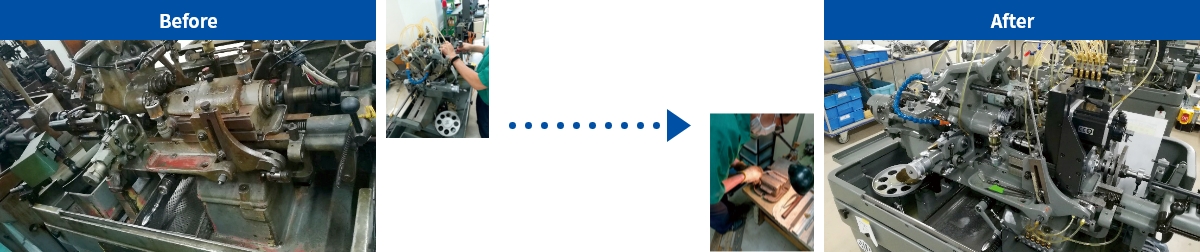

Maintenance and Regeneration of Production Facilities

Within our Group, we regularly renew aging production facilities, such as repairing or replacing worn-out components, in order to keep those facilities functioning properly, maintain effective resource utilization, and limit the need for waste disposal.

We also actively retrofit older production facilities by installing or integrating modern technologies to enhance functionality, maintenance capabilities, and energy efficiency. In the case of key equipment such the cam-type automatic lathe in prototyping models, retrofitting can result in an up to 20% increase in energy efficiency.

Transportation and Sales

We are working on reducing the size and weight of packaging, minimizing the use of foam materials, promoting the use of reusable boxes, and incorporating labels that encourage sorting and recycling as per regulations.

Collection and Recycling

We are engaged in the collection and recycling of used products and consumables through collaboration with sales outlets, industry associations, and other channels.

| Products, etc. | Participating organizations |

|---|---|

| Collection of button batteries | Button Battery Recycling Promotion Center (Battery Association of Japan) |

| Small Rechargeable Batteries | Japan Portable Rechargeable Battery Recycling Center (JBRC) |

| Containers and packaging | Japan Containers and Packaging Recycling Association |