Creating Value through

Business & Products

While cherishing the great trust we have built since our founding,

we provide various values to our customers and society with the technological prowess that has led the times,

and the sensibility and challenging spirit that will pioneer the future.

INDEX

The businesses and products of the Seiko Group

Since Seiko's founding business is the watch business, we have been striving to improve accuracy since our inception, and to manufacture wristwatches composed of small precision parts, we have continuously refined our precise technological capabilities.

This uncompromising pursuit of accuracy and technology has produced high-quality products and services, and this commitment to quality has extended beyond products to customer service and the services we provide, as well as to each business and department, and has been passed down through generations.

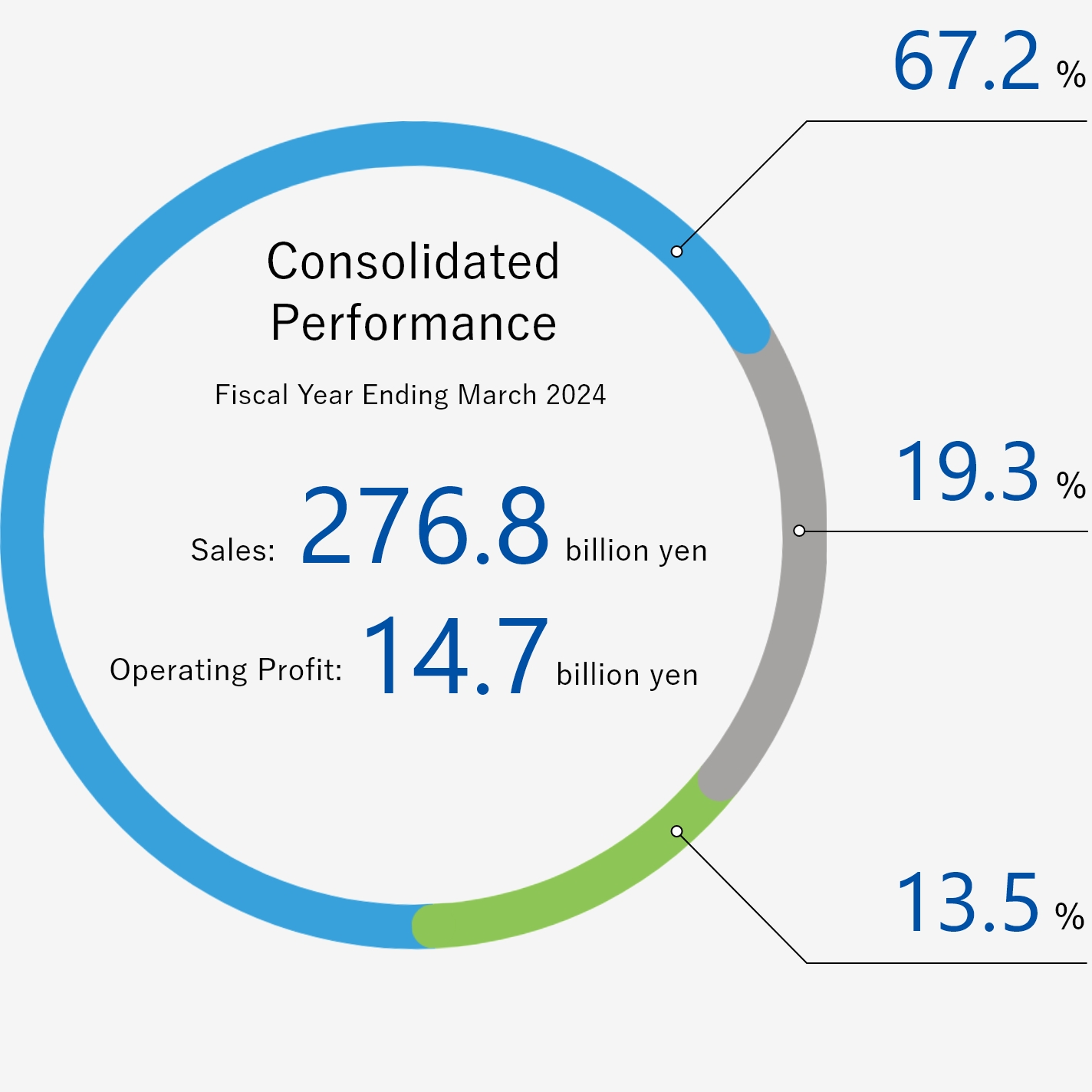

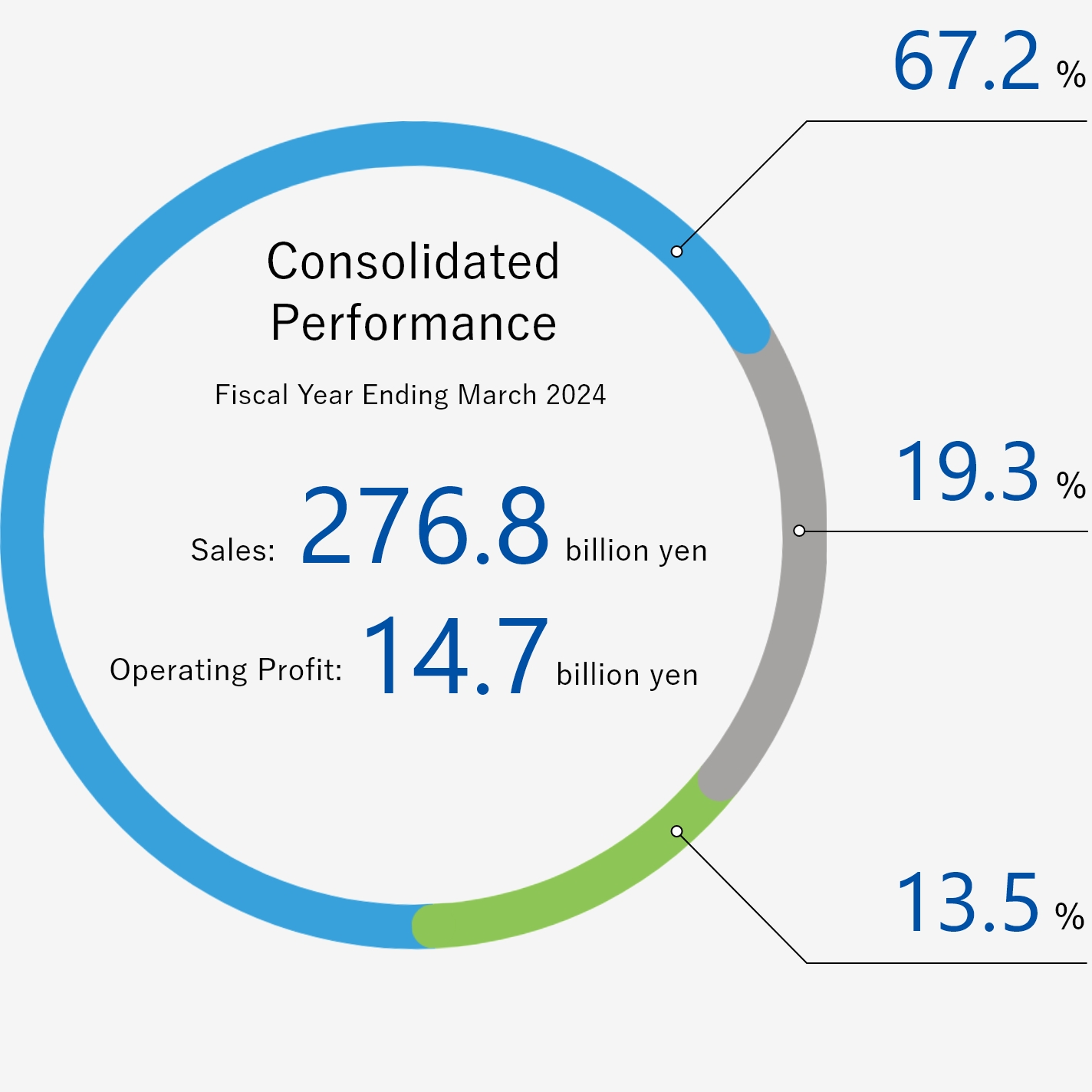

Group business performance

- Emotional Value Solutions

Domain - Sales: 2,042 (100 million yen)

Operating Profit: 223

(100 million yen) - Watch Business, Clock Business, Wako Business

- Device Solutions

Domain - Sales: 621 (100 million yen)

Operating Profit: 29

(100 million yen) - Device Solutions Business (electronic devices, precision devices, printing devices, others)

- System Solutions

Domain - Sales: 478 (100 million yen)

Operating Profit: 50

(100 million yen) - System Solutions Business (system-related, IoT-related, payment-related), System Clocks/Sports Timing Business

Three Business Domains of the Seiko Group

Strategic Domain

-

Emotional Value Solutions Domain

-

We create products and services with high functional, emotional, and social value, filled with the aesthetic sense and dedication that impresses customers, starting with watches and clocks.

For more details,

click here.

-

Device Solutions

Domain -

By providing high functionality and high quality that society demands through device solutions created by technological innovation, we contribute to the realization of Society 5.0 (solving social issues by merging cyber and physical spaces).

For more details,

click here.

-

System Solutions

Domain - We provide social innovation through one-stop ICT solutions, achieving sustainable growth. By providing sustainable value that meets customer needs, we contribute to enhancing the value of our customers, society, and the group.

For more details,

click here.

Business Areas and Products

Emotional Value

Solutions Domain

Device Solutions

Domain

System

Solutions Domain

Eyewear Business

As one of the few companies in the world that handles both lenses and frames, we provide glasses that achieve the highest and optimal performance.

We are a company with a long history and track record, widely recognized in the eyewear markets of Japan and the world. (Equity-method affiliate)

Seiko: The more you know, the closer you feel

Seiko's businesses are widely integrated into our daily lives. Here, we introduce the group's products around you.